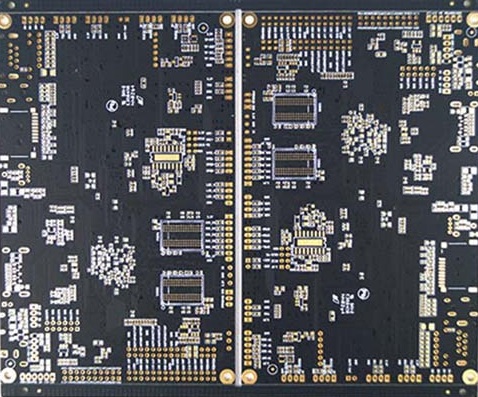

PCB Prototype

Before you order a full run of printed circuit boards for your project, you need to make sure your design works perfectly. To do this efficiently and cost-effectively, you need to create a prototype of your board — a small run of your design to test its functionality. You don't want to lose precious time on a lengthy prototyping process, though. That's why you need to work with a PCB company like Raica that can get you accurate, cost-effective prototypes quickly. Once you're satisfied with your prototypes, we can also complete your full production run with the same commitment to quality and efficiency.

More Information

|

PCB Prototype |

|

|

PCB Prototype Features |

Capability |

|

Quality Grade |

Standard IPC 1-3 |

|

Number of Layers |

1 – 32layers |

|

Order Quantity |

1pcs + |

|

Build Time |

2 – 15 days |

|

Material |

Rigid: FR2, CEM-1, CEM-3, FR4 (standard – halogen-free – high performance) including ShengYi, Iteq, Elite Materials Corp., NanYa, Kingboard, Grace, TUC, Meteorwave |

|

Flex: PI, PET Including Taiflex, Dupont FR & AP, Panasonic, ShengYi, Doosan. Hanwha, SF305 |

|

|

Metal Core: Metal Core Aluminum based material Including Bergquist MP, HT & CML, ITEQ T-Lam, Laird TLAM SS Taiflex, Dupont FR & AP, Panasonic, ShengYi, Doosan. Arlon,Ventec and suggested local material brand( for detail pls contact our sales) |

|

|

Board Size |

Maximum 610mm*1200mm (24” * 47″”) |

|

Board Thickness |

Rigid PCB : 0.15mm – 10 mm |

|

FLEX PCB: 0.05mm – 0.16mm |

|

|

Board Thickness tolerance |

/ |

|

Copper Weight |

1.0oz – 15.0oz |

|

Inner Layer Copper Weight |

0.5oz – 12.0oz |

|

Min Trace/Space( track/gap or width/space) |

2mil/2mil (0.05mm/0.05mm) |

|

Solder Mask Color |

Green, White, Blue, Black, Red, Yellow or others |

|

Silkscreen Color |

White, Black or others |

|

Surface Finish |

ENIG / GF / OSP / I Ag / HASL (lead) / HASL (Leadfree) / Plating Au/Ni/ Immersion Sn / GF+OSP / GF+HASL / OSP+ENIG /IAG+GF/Isn+GF |

|

Min Annular Ring |

5mil |

|

Min Drilling Hole Diameter |

mechanical: 0.1mm |

|

laser : 0.05mm |

|

|

NPTH Hole Size Tolerance |

±0.025mm |

|

PTH Hole Size Tolerance |

±.003″ (±0.08mm) – ±.006″ (±0.15mm) |

|

Surface/Hole Plating Thickness |

20μm – 30μm |

|

SM Tolerance (LPI) |

.003″ (0.075mm) |

|

Aspect Ratio |

20:1 (board thickness: hole size) |

|

Test |

10V – 250V, flying probe or testing fixture |